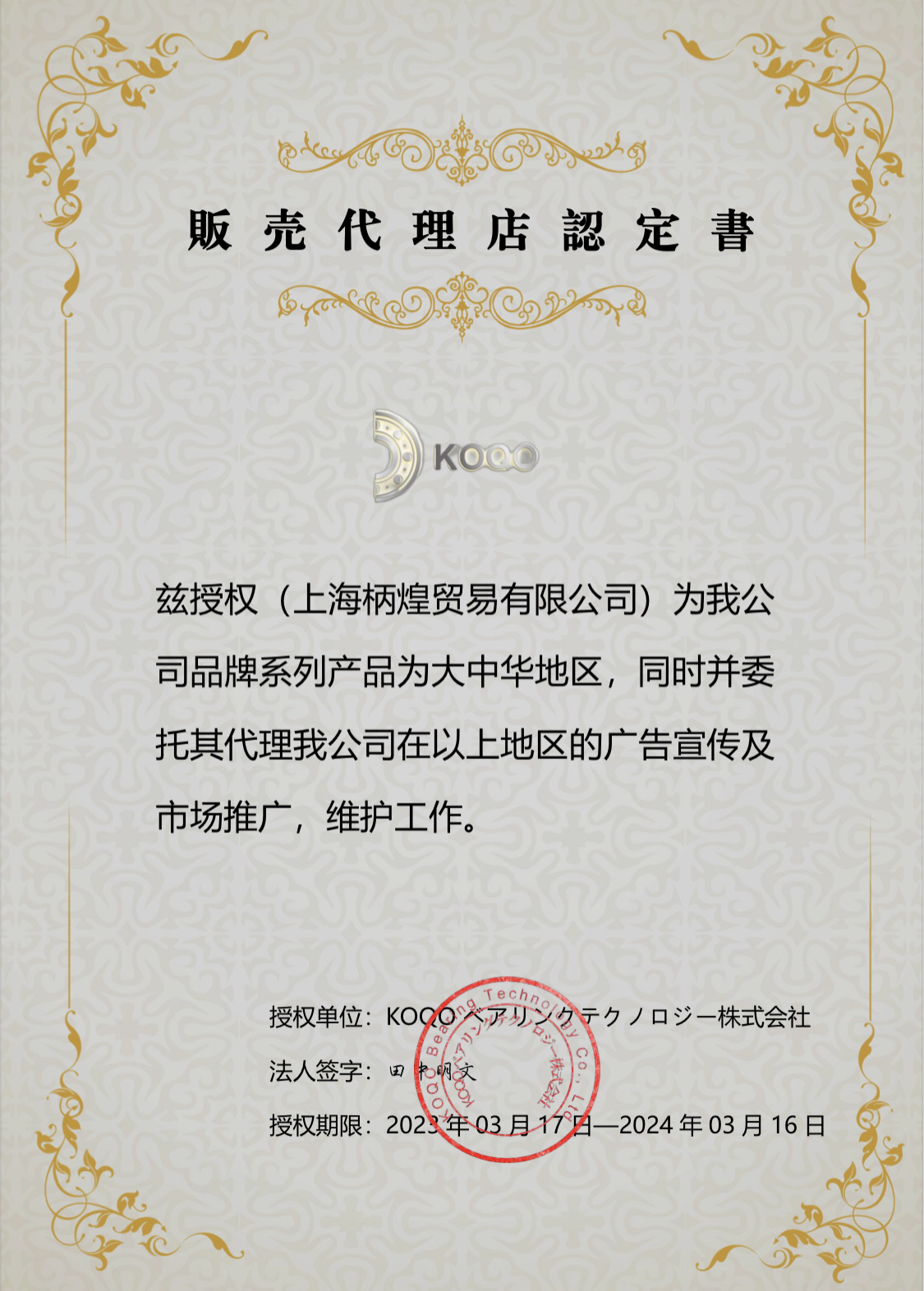

Shanghai Binghuang Trading Co., Ltd. is the agent for KOQO brand series products in the Greater China region, and is responsible for KOQO's advertising, marketing, and maintenance work in the Greater China region. At the same time, our company also operates bearing brands such as SKF bearings, KOYO bearings, FAG bearings, NSK bearings, TIMKEN bearings, IKO bearings, INA bearings, and NACHI bearings.

MORE>>Shanghai Binghuang Trading Co., Ltd. deals in various types of bearings, including deep groove ball bearings, angular contact ball bearings, aligning ball bearings, thrust ball bearings, cylindrical roller bearings, tapered roller bearings, spherical roller bearings, thrust Roller bearings, needle roller bearings, spherical bearings, linear bearings and other metric bearings.

MORE>>Complete categories and numerous models, which can be used in various fields.

We have a wealth of inventory for you to choose from and can be shipped in time after ordering.

Provide you with pre-sales and after-sales support around the clock and provide bearing solutions.

We have reached strategic cooperation with a number of logistics companies to ensure that your bearings can be delivered in a timely and safe manner.

This is to certify that Shanghai Binghuang Trading Co., Ltd Unified social credit code :91310120MACT969168 Demonstration unit of honest operation is. Executive standard of credit rating:O/HXRC001-2022.

Details>>

We hereby authorize (Shanghai Binghuang Trading Co., Ltd.) to provide our company's brand series products for the Greater China region, and at the same time entrust it to act as our company's agent for advertising, marketing, and maintenance work in the a

Details>>